PRODUCTS

Mobile Dust & Fume Extraction and Filtration, Stationary Dust & Fume Extraction and Filtration, Welding Tables, Welding Robot Cabinets, Acrobat Arms for Central Systems, Central Ventilation and Filtering Solutions as well as Welder Protection Systems and Snail Fan Units.

MOBILE FUME EXTRACTOR UNITS

STATIONARY EXTRACTOR UNITS

They are stationary units with improved mobility for narrow working areas. Strong filtering power with Double or Single Acrobat arms.

DOWNDRAFT WELDING TABLES

It has been developed for table-top works with its strong suction capabilities. Creates an efficient workspace with its mobile feature.

ROBOTIC WELDING HOODS

Developed for Robotic Welding Industries. It prevents fumes and gasses spreading to the environment and harming human health.

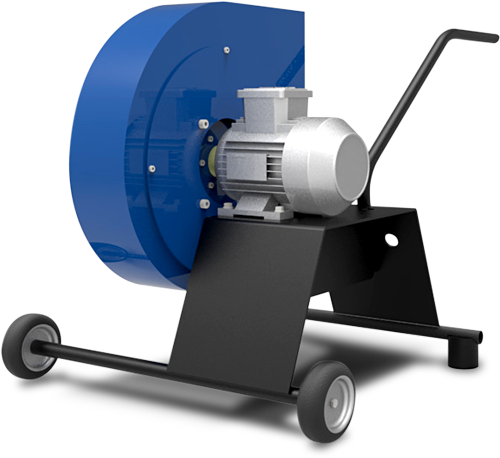

FUME EXTRACTION SNAIL FANS

Suitable for solutions that do not need filtration at the traction point. It can also be used as a part of central smoke evacuation systems.

FUME EXTRACTION ARMS

It is designed to be connected to central fume evacuation or fume extraction systems. It is suitable for suction of smoke, gas, steam and light dust.

TORCH HIGH VACUUM

Ideal for use with fume extraction Mig-Mag & Robotic welding torches and angular materials welding process.

WELDING SAFETY EQUIPMENT

Also known as Welding Screens or Welding Safety Curtains. Separating individual and factory areas provides protection against harmful rays and welding spatter.

If harmful particles such as dust, welding fumes, odor and oil-mist are released from the machines you use during your production and solving this problem becomes complicated for you, we recommend you to read our article from start to finish.

With the development of technologies used in the industry, production practices are changing and developing day by day.

When you invest in a new CNC machine, welding machine, plasma, laser, press, angle grinder, saw, heat treatment furnace, vertical machining center or industrial robot, you make a decision after examining it to the finest detail.

Then you invest in the most accurate systems that you are convinced of to improve your production and produce better quality, faster and error-free products.

After commissioning all these systems and operating for a short period of time or during an inspection, harmful particles from these machines will definitely be a big problem.

If you notice these problems during inspections, you may have limited time to solve them or you may not have enough budget left in your investments for the current year.

[Click here to review some of our sales sources]

For these reasons, it will be of great benefit to solve the problem from the beginning by considering the extraction and filtration system simultaneously when you invest in the machine.

Regardless of the conditions and results, it is better not to rush until you find the right solution rather than making an unnecessary and/or wrong investment.

Click to read our article 15 Things to Consider When Buying Smoke Extraction and Filter Systems.